Introduction

Foam may seem like a simple material, but in industrial and marine engineering, it becomes a technical powerhouse when processed correctly. Foam conversion transforms ordinary foam into tailored solutions that can reduce noise, improve safety, provide thermal insulation, and withstand harsh environments.

In this article, we’ll explore how foam conversion helps industries like marine, automotive, construction, and manufacturing. We will also explain how Acoustafoam supports engineering projects with advanced foam processing and expert guidance.

1. What is Foam Conversion and Why Is It Important?

Foam conversion is the process of turning foam into a usable product. Whether it’s cutting, shaping, laminating, or profiling, foam conversion enables foam to meet specific functional needs. This is especially important in industries where precision and performance matter.

In marine engineering, foam conversion is used for insulation and sound control in engine rooms and cabins. In industrial environments, foam conversion helps reduce vibration, noise, and heat.

2. Acoustafoam: The Technical Foam Conversion Experts

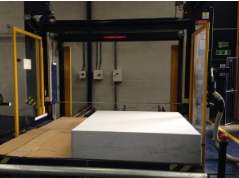

Acoustafoam is a leading company specializing in foam, rubber, and plastic component manufacturing. They process materials from blocks, sheets, and rolls using high-end machinery such as:

- Band saw

- Profiled slitter

- CNC profiling machine

- Water jets

- Laminator

- Die cut press

- Spray booths

These tools allow them to produce technical foam products that solve real engineering problems. Their expertise enables them to support complex applications across different sectors.

3. Foam Conversion Techniques for Engineering Applications

CNC Profiling

CNC profiling is a precision method that allows foam to be shaped into custom forms. It is especially useful for acoustic panels, insulation blocks, and components that need exact dimensions.

Water Jet Cutting

Water jet cutting offers smooth and accurate foam cuts without heat damage. This is ideal for sensitive materials used in marine and industrial environments.

Lamination

Lamination bonds foam to other materials, increasing strength and creating composite solutions. This is valuable for vibration damping and thermal insulation.

Die Cutting

Die cutting is perfect for producing large quantities of identical foam components quickly. It is commonly used in automotive and manufacturing applications.

4. Industrial Applications of Foam Conversion

Noise Control in Factories

Industrial environments often face high noise levels from machinery. Foam conversion helps create sound absorption panels, reducing echo and improving worker comfort. This is essential for safety and productivity.

Thermal Insulation

Heat management is critical in industrial settings. Foam conversion produces thermal insulation solutions that prevent heat loss and protect equipment.

Vibration Dampening

Foam components can be used to absorb vibration in machinery and reduce wear and tear. This increases the lifespan of equipment and reduces maintenance costs.

5. Marine Engineering: Where Foam Conversion Makes a Big Difference

Marine environments are harsh and demanding. Boats and yachts need insulation solutions that can handle moisture, heat, and constant movement.

Engine Room Sound Absorption

Acoustic foam is commonly used in engine rooms to reduce noise and improve comfort. Class 0 foam is especially valuable because it is fire-resistant and safe for marine environments.

Thermal Insulation for Engine Rooms

Engine rooms generate high heat. Foam converter creates thermal insulation panels that keep the engine compartment safe and stable.

Marine Cabin Comfort

Foam conversion can be used to create cabin insulation and soundproofing, improving the overall comfort of the vessel.

6. Class 0 Foam: Safety Meets Performance

Class 0 foam is specially treated with a mineral compound to provide nil burn rate, making it suitable for high fire-risk environments. It is flexible, non-dusting, and easy to apply to curved surfaces.

Key Benefits of Class 0 Foam

- Fire-resistant and non-combustible

- Flexible and easy to shape

- Non-toxic and safe to handle

- Available in sheets, rolls, and profiles

- Can be combined with facing materials and coatings

Class 0 foam is widely used in engine rooms, generator canopies, heavy vehicles, and industrial facilities.

7. High-Density Class 0 Profile for Superior Acoustic Performance

High-density Class 0 profile offers exceptional sound absorption and is ideal for applications where durability is essential. It is non-fibrous, meaning it won’t erode or migrate in airflow.

For marine and high-heat applications, Acoustafoam offers a foil-facing option with C03/9 PVC acting as a sound barrier.

8. Acoustic Foam: Effective Sound Control (Not Full Soundproofing)

Acoustic foam is designed to reduce echoes and improve sound clarity. It is most effective for mid to high frequencies, and it increases surface area through shapes like wedges and pyramids.

Where Acoustic Foam Works Best

- Recording studios

- Home theaters

- Offices

- Public spaces like gyms and auditoriums

Important Installation Tips

- Cover at least 20–30% of the wall for noticeable effects

- Place foam at reflection points and corners

- Use spray adhesive or mounting brackets for strong adhesion

Note: Acoustic foam is not a full soundproofing solution. To block sound, additional materials such as mass-loaded vinyl or drywall are required.

9. Foam Conversion Benefits for Engineering Projects

Foam conversion is valuable because it offers:

Benefits

- Custom designs for exact specifications

- Improved sound absorption and insulation

- Fire-safe solutions like Class 0 foam

- Durable and long-lasting components

- Environmentally friendly options

- Fast production and high accuracy

These benefits make foam conversion ideal for industries that require high performance and safety standards.

Conclusion

Foam conversion is a crucial manufacturing process for industrial and marine engineering. It transforms foam into high-performance solutions for noise control, thermal insulation, vibration damping, and fire safety.

Acoustafoam’s expertise in foam conversion, along with advanced machinery like CNC profiling, water jets, and lamination, enables them to deliver customized foam solutions for a wide range of applications.

If you are looking for professional foam conversion services for industrial or marine engineering, contact Acoustafoam using their contact form. They are ready to help you find the best solution for your project.